This complete guide to embroidery hooping will cover:

- The difference between commercial & home embroidery hoops.

- Give you a basic tutorial on how to properly hoop fabric without, well Jumping through hoops.

- Show you some useful techniques & tricks that’ll help you hoop easier.

- The difference between hooping and floating.

- Explain hooping aids and why / when you might need them.

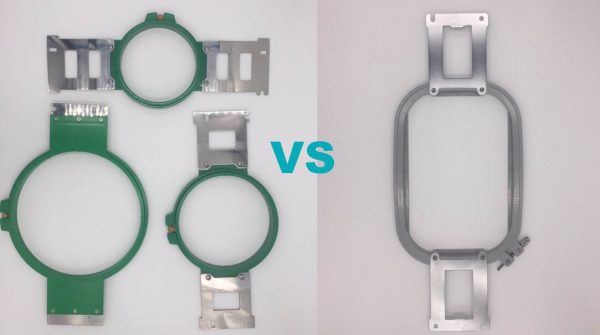

Commercial vs. Home Embroidery Hoops

Having come from the commercial side of embroidery, I must admit that one of the things that shocked me most when entering the home or hobbyist embroidery industry was the shape of the hoops

You see, in the commercial embroidery industry, the shapes of most hoops are circular & round. While in the home embroidery industry, most hoops are square or rectangular which is why you get sizes like 5 x 7 hoops.

Now logically, the commercial (or circular) hoops do make more sense. The reason is because with the rectangular hobbyist hoops, there are 4 corners where the fabric is held securely. However, the long straight areas of the hoop between the corners are not held as tight or securely. This leads to the fabric becoming loose and causing issues like design misregistration & puckering.

Now with the commercial hoops being circular, the material is held down securely and evenly within all areas of the hoop. Instead of only having 4 strong corners, the pressure is evenly dispersed throughout the entire hoop which makes the fabric less likely to become lose & pull inwards. Think of it like a drum: a drum is circular so that the drum skin (as they call it) can be stretched evenly across the drum to make it tight.

To this day, I personally do prefer to use circular hoops over square or rectangular-shaped ones because it does a better job of holding your fabric & stabilizer securely in place. However, it is in no way a must. Some home and commercial crossover machines do come with circular hoops. But you’re often able to custom order circular hoops for most home machine brands, too.

Once again, you in no way need to have circular hoops. I’ll show you some helpful tips & tricks on how to secure the long straight areas of rectangular hoops in the Hooping Tips, Tricks & Techniques section below. But first, let’s cover some hooping basics with a quick tutorial.

Machine Embroidery Hooping Tutorial

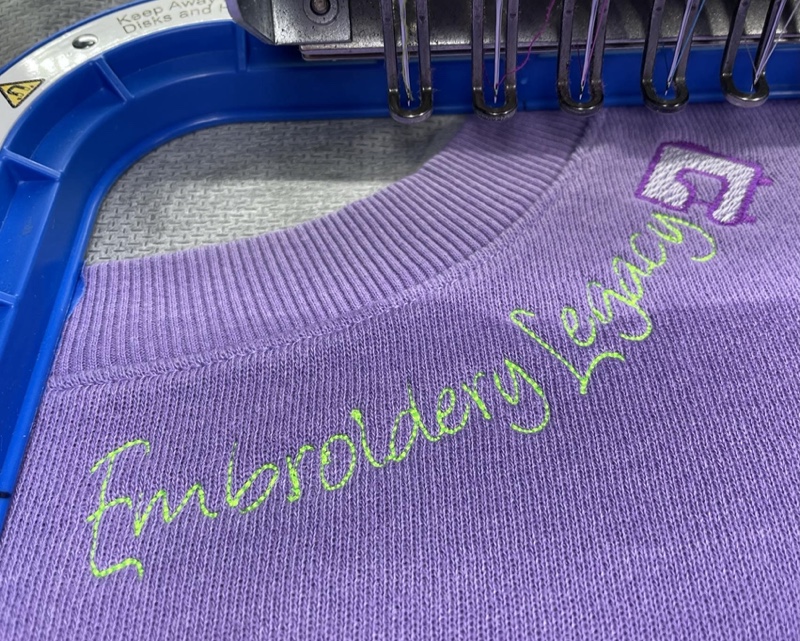

Properly hooping a garment will increase the correct registration of a design, and reduce puckering and movement.

Step 1: Get Your Hoop & Fabric Ready

The first step towards proper hooping is to grab the piece of material that you’ll be stitching on, fold it in half, and give it a tiny bit of pressure. This will give you a measurement of how thick the fabric is when folded and gives you a visual guideline showing you how to properly pre-adjust the space between each half of your hoop.

The idea is that when you pre-adjust the hoop to the right size beforehand, you won’t play around tightening it after the material is already hooped, which causes hoop burn on the material.

You will then take your hoop and pull on the corner that has the adjustable knob and loosen or tighten it to make the separation between each piece of the hoop roughly the same size as the visually measured folded fabric.

Step 2: Hoop Your Material

Next, you will place the bottom half of your hoop on the table in front of you so that the adjustable corner with the knob is the furthest away from you.

After properly laying your material and stabilizer on top of the bottom half of the hoop that is on the table, you will take the top half of the hoop and in one swift motion, push it forward and down into the bottom half of the hoop to pop it into place. If pre-adjusted properly, there should be a little bit of resistance, but you shouldn’t be fighting with the top piece of the hoop to press it in.

Instead of tightening the hoop by turning the knob afterward, while the hoop is still on the table grab the material sticking out of the longer sides of the hoop and pull it gently. Then pick up the hoop and push the corners of the hoop in slightly, making it drum-tight and machine-ready.

That’s it, now you’re ready to place your hoop on your machine and start stitching!

Embroidery Hooping for Beginner’s Video Tutorial:

If you’re more of a visual learner, here’s a great quick tip video I put together explaining the process.

Hooping Tips, Tricks & Techniques

Now that you know how to hoop and the difference between commercial & home embroidery hoops, here are some helpful techniques and tricks that’ll help you tackle any embroidery hooping project:

1. Use the Correct Hoop Size

Simply put, you will always get the best results if you use a hoop that is closest in size to the embroidery design you are running. For example, if your design is 3.5 x 3.8, use a 4 x 4 hoop, not a 5 x 7.

This is a basic principle but surprisingly, quite a few embroiderers don’t follow it.

2. Use T-pins for Large Rectangular Hoops

If you ever need to secure your fabric in a large rectangular hoop, I suggest you use T-pins to hold the fabric securely in place.

For this technique, you’ll hoop your fabric as you normally would (see the tutorial section above for more details). Once this is complete, you’ll use T-pins to secure the stabilizer or fabric in place & stop any potential movement. The T-pins should be inserted where the stabilizer or fabric sticks out between the two hoop frames after being hooped. They should be inserted flush with the frame. This way, when the stabilizer or fabric begins to pull in around the loose areas of the frame, the T-pins will be there to catch against the frame and stop any movement.

We recommend inserting these T-pins around the long straight areas of hobbyist hoops as these sections are not held as tightly or securely. The corners will not require T-pins.

Here’s a quick video to show you the technique in action:

3. Use Double Sided Tape

Using double-sided tape is a great technique when dealing with sheer, slippery, or stretchy fabrics. The reason being that the stabilizer which touches the outside part of the hoop does its job as stated, its stability holds to the plastic part of the outer hoop. The issue of puckering within a design often occurs when the material touching the plastic of the inner hoop doesn’t grip the material. So, when you have one part holding securely and the other slipping, the result is distortion and puckering within the design.

Applying double-sided tape to the outside of the inner hoop where the material touches the hoop eliminates the slipping between the stabilizer and fabric and will give you much better results.

The best part is, the tape will work for multiple hoopings, until it loses its stickiness, then you simply remove and reapply a new piece. I’ve also found that it doesn’t harm or leave any residue to most fabric types. Essentially it does almost the same job as the t-pin technique but is less invasive to the fabric.

This technique is a win-win in my books.

Here’s a quick video to show you the technique in action:

4. Don’t Over-Tighten the Hoop

Remember not to over-tighten the hoop by aggressively adjusting the knob after the fabric has already been hooped. I see this all the time with embroidery beginners; they first hoop very loosely, then aggressively turn the knob to tighten the hoop. A finger-tight turn or two may sometimes be needed but never take a screwdriver & tighten the hoop to the max. This is a huge waste of time, causes fabric burn, and is harmful towards your embroidery stitch out.

Instead of tightening the hoop by turning the knob afterward, while the hoop is still on the table grab the material sticking out of the longer sides of the hoop and pull it gently. Then pick up the hoop and push the corners of the hoop in slightly, making it drum-tight and machine-ready. Remember that a simple finger-tight turn at the end may sometimes be required but not always. You don’t want a loose hoop allowing the fabric to slip but you certainly don’t want to damage your hoop or fabric by over-tightening.

Floating Embroidery vs. Hooping: What’s the Difference?

I’ve seen a big movement recently where people are floating their embroidery. Floating in machine embroidery essentially means that the user hoops a piece of stabilizer and then places (floats) the material/item being embroidered onto the stabilizer.

I’m not a big fan, as this is not a one-size-fits-all way of hooping. My rule of thumb is if you can’t hoop an item, or if it is specifically digitized as an in-the-hoop project that requires you to float pieces of fabric, then you should float it. But as far as I’m concerned, it should be a last resort if the application is directed to a finished garment.

You will always get better results if you securely hoop your stabilizer and fabric. One of the biggest registration problems I see is things not lining up on well-digitized designs because the item was floated and not hooped securely.

If you need to float an item or material instead of hooping it, I strongly suggest extra measures are taken to ensure better results. These can include:

- Hoop your stabilizer and pin your material to the hooped stabilizer. It is simple and quick, but pins can leave marks on delicate fabrics, and slinky or stretchy materials need more support.

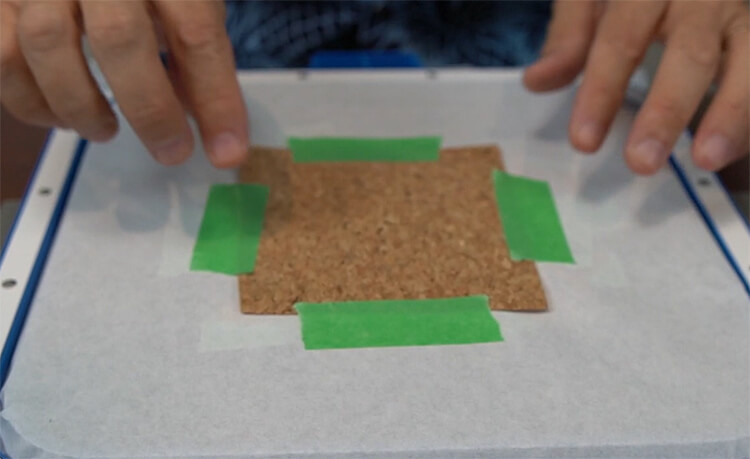

- Hoop your stabilizer and tape your material to it. This works well for small items like patches.

- Hoop your sticky stabilizer. Cut a window slightly larger than your embroidery area and stick down the fabric. This works well but can be costly.

- Basting stitches. This is an easy, stable way of aiding floating in the hoop. Simply digitize a framed running stitch around your embroidery area. Using long stitches makes it easier to remove them after your garment is finished embroidering.

Be careful; this can often cause damage to the base material. Stitching a basting box works well but remember, if you are working on vinyl, leather, or other materials, a basting box can leave marks. - Fusible stabilizer. You hoop this stabilizer and then use a mini iron to secure the garment or project to the base in only that spot. Caution: this is permanent, so triple-check before that iron goes near the fabric!

- Adhesive spray. Be sure to spray on your stabilizer before hooping it. Spray adhesive and sticky stabilizers can leave a residue that gum up your machine and remain on the fabric. Always ensure you follow the package’s directions or can for the best results.

When To Use The Floating Method In Machine Embroidery

If you decide to float your garments, here are some things to keep in mind:

- Float smaller projects such as patches, quilted pieces, socks, etc.

- Large garments are too heavy for floating and can get caught in a flatbed machine. Of course, you can float your garment but remember to keep watch throughout the stitching process to “tend” the garment.

- Floated in the hoop (ITH) projects

Embroidery Hooping Aids, Stations & Boards Make it Easy

If you’ve ever tried hooping with magnetic embroidery hoops, I don’t have to explain the perks to you. If you haven’t, well, you’re in for a treat! Magnetic hoops, like Mighty Hoops, make hooping quicker, easier, and more accurate.

Now, I would personally recommend Mighty Hoops for anyone who:

- Has trouble hooping.

- Hoops difficult items (like baby onesies, sleeves, embroidery buddies, socks, etc).

- Owns an embroidery business.

- Makes multiple similar items at once (for example 10 shirts).

- Has problems with hooping or doesn’t enjoy hooping

These hoops simplify the process, speed things up, and reduce the chances of mistakes, so you can avoid re-hooping altogether.

What makes Mighty Hoops stand out is their innovative magnetic design, which works with various multi-needle machines. They ensure perfect, accurate hooping every time—without hoop burn or material shifting.

Not to mention, they actually make hooping fun!

When you purchase your Mighty Hoops through us, you’ll also get exclusive bonuses you won’t find anywhere else. It’s the perfect opportunity to take your embroidery projects to the next level! Click here to learn more about Mighty Hoops now.

What’s Next?

Hopefully, this article has taught you a thing or two about hooping.

If you’re new to machine embroidery, I would suggest that you try hooping a few items following the steps provided in the tutorial section above. Although hooping isn’t the most fun part of embroidery, it is one of the most important, and as the old saying goes, practice makes perfect.

Now if you’re more experienced and landed on this article in hopes of finding an easier way to hoop, I highly suggest you check out the Mighty Hoops (remember to use our code for free shipping and exclusive bonuses!) It makes the entire hooping process much faster, easier, and less frustrating.

If you enjoyed the videos provided above, please don’t forget to subscribe to our YouTube channel by clicking here! I appreciate your support.

Until next time, keep on hooping, learning, and creating beautiful embroidery!

Thanks so much. I’ve embroidered for years–on my third machine–and still learned a thing or two.

Always something new to learn with embroidery 🙂

Will Janome 550el work with your hooping device Work with my hoops?

Yes, our hooping stations are compatible with all home and commercial hoop brands 🙂

An amazing video on hooping, I’m still learning so much. Thanks so much for the great tips!!

Great to hear! Thanks for reading Patty 🙂

Hi, a Brother PE 800. How to hoop a double layer dog bandana. Usually not a problem, but had a heavy flannel that would not fit in hoop. I stitched layers together where it was to be monogrammed, Floated it, but it skipped couple stitches. Is there a better way? Thank you!

Hi Judy, the best place to post would be in our FB Group as we personally don’t have that make or model of machine for our sampling.https://www.facebook.com/groups/EmbroideryLegacy/